Sustainable Coal Mining and Electricity Generation: With Special Reference to Dahanu Thermal Power Station

Corresponding author Email: sugat.tajne@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.15.Special-Issue1.06

Copy the following to cite this article:

Sustainable Coal Mining and Electricity Generation: With Special Reference to Dahanu Thermal Power Station. Curr World Environ 2020; Special Issue (Sustainable Mining). DOI:http://dx.doi.org/10.12944/CWE.15.Special-Issue1.06

Copy the following to cite this URL:

Tajane S, Kamthan M. Sustainable Coal Mining and Electricity Generation: With Special Reference to Dahanu Thermal Power Station. Curr World Environ 2020; Special Issue (Sustainable Mining). Available from: https://bit.ly/2VbdIUl

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 30-05-2020 |

|---|---|

| Accepted: | 21-06-2020 |

| Reviewed by: |

Bijendra Kumar

Bijendra Kumar

|

| Second Review by: |

DelfÃn Ortega Sánchez

DelfÃn Ortega Sánchez

|

| Final Approval by: | Prof BB Dhar |

Introduction

Coal is mined for commercial purpose in more than 50 countries across the world. The International Energy Agency in its 2019 report1 on coal information states that the coal production has increased from 3000 million tonnes (Mt) in 1971 to 7000Mt in 2019. The report provides that China ranks on the top position in terms of coal production (3,523 Mt) followed by India (716 Mt) and United States at third position (702.3 Mt). The environmental impact of coal industry has attracted attention across the globe. Climate change is one of the greatest challenge of our time. The environmental and health impact of coal mining has always been a matter of concern since past several years.

The frequent outbreak of fires at the mining sites have a serious impact on environment and health of people as these fumes contain Sulphur compounds laced with heavy metals like mercury, lead and arsenic, Bolormaa Oyuntsetseg et al., (2012).2 Also they contain high concentrations of volatile organic compounds like Benzene, toluene and xylene which are known to cause cancer. Dust which is observed at these mining sites is a major source of Particulate Matter (PM) 10 pollutants. The air around these coal mines is filled with dust is constantly kicked up by movements of coal trucks within the mines. Blasting which takes place at least two-three times a day in the open cast mine is another important source of pollution. With each blast, tonnes of earth material is lifted and forms dust clouds accompanied by a hailstorm of shattered rocks. Another source of dust at the coal mines is the loading and unloading of coal, drag lines digging, dust from stockpiles and discard dumps which is transported by winds to nearby areas, Hossain et al., (2015).3 PM 10 particles present in the dust are so small that they can enter deep inside the lungs and can cause number of health impacts including high blood pressure, heart attacks, strokes, asthma and premature deaths. The workers who work in coal mines are prone to spectrum of diseases like to coal mine dust lung disease, coal workers pneumoconiosis (CWP) and silicosis. Coal mining also leads to ruining of land structures on an immense scale by shifting earth and rocks on significant scale, Howladar (2016).4 These have significant impact on the flow of groundwater. The acidic water which comes out while drilling contains heavy metals. This process is known as acid mine drainage. This drainage flows in the nearby streams and water bodies contaminating them and making them unsafe for use.

In order to minimize the impact of mining on environment and health it is necessary that government and corporates should do sustainable mining. Sustainable mining involves reducing the environmental and health impacts of mining. Strategies for assessing the sustainability of mining involves use of methods and machinery which will improve various environmental performance metrics. Some of the metrics for environmental sustainability in mining include efficient resource consumption, minimizing land disturbance, reduction in pollution and reclamation of exhausted land mines. This can be obtained by use of modern instruments and machinery. Use of binderless coal briquetting technology is one such technique which allows coal mines to upgrade discarded thermal coal into compacted, transportable and useable briquettes of higher value. In order to reduce exposure of pollutants on long mine walls use of water spray and foam applications can be used. The canopy air curtain technology should be used on coal haulage vehicles and optimizing filtration and pressurization systems for enclosed work spaces are some of the techniques which can be used at coal mines. Additionally it is also important that Environmental Impact Assessment of proposed mining site be undertaken to analyze the impact of mining on the environment and health of people. Mining must necessarily be carried out within the carrying capacity of the environment and available infrastructure facilities. It is also important that local communities are consulted in preparation and implementation of mine closure plans.

Sesa Sterlite Limited has done notable work in adopting biotechnology solutions in order to recover the mine site after closure of mines by improving the degraded land to acceptable levels. Noamundi Iron Ore Mine under Tata Steel Limited and Rampura Agucha Zinc Mine under Hindustan Zinc Limited have adopted world class sustainable mining interventions with regard to disposal of mine-tailings and reuse of mine-water after beneficiation process, Indian Chamber of Commerce (2018)5

While these techniques are undertaken at coal mining sites, it is equally important that Thermal Power Plants which process these coal for generation of electricity are equipped with equally advanced technologies to minimize their impact on environment. Burning of coal in thermal power plants is one of the important source of air pollution.

It is important to ensure that technologies are adopted by thermal power plants that will help to minimize pollution and ensure clean and sustainable energy. Pachouri et al., (2020)6 in his discussion paper highlights the issue of coal fired power plants as the largest emitters of Carbon Dioxide (CO2), Sulphur Dioxide (SO2), Oxides of Nitrogen (NOX) and Particulate Matter (PM) 2.5 and PM 10. It states that out of the total environmental pollution in 2016, power sector reportedly accounted for 51% of SO2; 43% CO2; 20% of Oxides of Nitrogen NOX and 7% of PM2.5 emissions in India.

The continued exposure to these pollutants leads to various airborne and cerebrovascular diseases.7 In the year 2011-2012, emissions from Indian Coal based thermal plants resulted in 80,000 to1,15,000 untimely death as well as more than 20 million asthma cases due to exposure to PM 10 pollutants. India’s ambient air pollution caused premature mortality of 0.67million in 2017.8 Water Pollution is another problem associated with coal fired plants especially those situated close to water bodies and coastal areas. Hot water released from the thermal plant brings changes to the water temperature. Even small temperature changes causes shock to aquatic life.9 Ash Ponds are created by the plants to deposit the incombustible coal residues. Cropper et al. (2013)10 in his study conducted found that these residues contain metals like Asbestos, Cadmium, Mercury and Lead. If not managed properly these residues cause land and water pollution due to seepage and leaching and ultimately water borne diseases. Gunatilake et al., (2014)11 in his study conducted in India estimated that the cost of pollution control technology around USD 12 billion if the retrofits were to happen at all eligible plants. This will add to an increase in tariff between INR 0.32 to 0.72 per kWh of electricity generated by these plants. The public health cost of air pollution arising from power plants far outweigh the cost of retrofitting. By merely spending US cents 0.28 per kWh, health impacts attributable to pollution from thermal power plants can be reduced from USD 0.125 per kWh to USD 0.0105 per kWh (Nkambule et al., 2017).12 The mortality and morbidity costs which India will have to incur due to PM 2.5 alone were estimated to be USD 128 billion and USD 11 billion respectively during 2015 - 2030 (Srinivas et al., 2018).13 If the emission trends of thermal power plants remain unchanged, projections estimate that these pollutants will cause an estimated 1.3 million deaths per year in India alone by 2015 (Health Effects Institute 2018).14

The environmental and health hazards can be mitigated if correct techniques are employed by the plant to minimize the emission of pollutants. Taking into consideration large demands of electricity from the residential, industrial, agriculture and commercial sectors it is not possible to completely do away with the coal fired plants at the current stage.15 Nonetheless, it is necessary that proper techniques and method are employed by the coal fired plants that will minimize impact on environment and heath of the people and simultaneously meet the demands of energy of the country in a sustainable way.

Research Objective and Methodology

The current research paper is written keeping in mind two objectives. Firstly to analyze the problem of coal mining in India and suggest measures which will help in sustainable and environment friendly coal mining. Secondly to study the technologies which can be used in Thermal Power Plants that will help to minimize the environmental pollution and help in deriving clean energy. In order to study the first objective doctrinal research is undertaken wherein literature related to coal mining is analyzed and studied upon to discuss the problem of coal mining and suggest measures for sustainable coal mining. In order to study the second objective non-doctrinal qualitative and quantitative research is undertaken of Dahanu Thermal Power Station (DTPS). The empirical component involved field visit to the DTPS and interviews with the authorities at the site. Data was collected from the site regarding the emission of different pollutants to analyze the impact of modern and efficient technologies used in DTPS in curbing pollution levels. No such study has been undertaken and hence it is novel.

Background of DTPS

DTPS is operated and maintained by Adani Power Limited. The plant is located in Dahanu region which is 120 km north of Bombay on the western coast of Maharashtra. The plant has two electricity generation units of 250 MW each making the total electricity generation capacity of the plant up to 500 MW. The plant is spread across a total area of 851 hectares. The plant is located in area of 100 hectares and the area reserved for ash ponds is 375 hectares. The plant also has residential colony for its departmental staff and employees. The site is situated predominantly in barren area having very few salt pans and is surrounded by sparsely populated region. The site is bounded by creek on three sides and western railway line on the east. The coal is brought by railways and also via sea. Domestic coal requirements are met from the mines of Madhya Pradesh, India while coal is imported from Middle East countries to meet the mandatory requirements of use of imported coal. The water required for generation of steam is drawn from the Surya Dam located nearby. It has once through cooling system and the requirement of cold water for cooling purpose is met from the seawater of creek.

The electricity is transmitted to Bombay to meet the electricity requirements of the city. The plant has a separate in house Environmental Monitoring Department which looks after the compliance of environmental laws.

The plant began its operations in 1996. The Environmental Impact Assessment was conducted in 1987 before setting up of the plant and extensive field studies were undertaken to analyze and study not just the technicalities of the plant but also the social and environmental aspects. Since, there are very few industries located in this region the background concentration of pollutants is also less. For effective dispersal of pollutants the plant has set up a tall chimney of 220 meters. Extensive computer studies were undertaken to establish ground level concentration of pollutants up to 50kms radial distance from proposed thermal power station. Continuous hourly wind data for period of 365 days was obtained before setting up the chimney of the plant. The site was appraised based on the availability of cooling water from the creek, suitability of the terrain, land available for disposal of ash for a period of least 25 years, methods for transporting coal and minimum impact on the surrounding environment. Based on a detailed investigation Dahanu location was chosen as this would meet optimally the various requirements for a viable power station.

Technologies Used at DTPS 16

- Flue Gas Desulphurization (FGD) Plant - DTPS was the first thermal power plant in the country to install an FGD plant in 2007. The main purpose of the FGD plant is to lower the Sulphur dioxide emissions from the plant. Wet scrubbing method using limestone to scrub gases is used in FGD to remove Sulphur dioxide from flue gases at DTPS. After installation, the Sulphur emissions has reduced by almost 90%.

- Electrostatic Precipitators (ESP) with Ammonia Dosing System - Combustion of coal generates flue gas. ESP helps to collect ash particles by using static electricity in the precipitators leaving clean flue gas through stack. ESP at DTPS operate at 99.99% efficiency. The ESP has six electric fields in series with a total collecting area 51840 sq.mt for each of the two units. In 2009 the plant obtained a patent for an innovative technique which helps to improve the efficiency of ESP. It is called ammonia dosing system. In this method ammonia is injected at the inlet of ESP which helps in advanced performance of ESP. This technique has helped to keep the Particulate Matter concentration below 50mg/Nm3 which is much below of the limit stipulated by MoEFCC which is 100mg/Nm3.

- Ambient Air Quality Monitoring Stations - For continuous monitoring of ambient air quality in nearby areas the plant has set up three Air Quality Monitoring Stations to monitor the emission of SO2, NOX and Particulates. These monitoring stations provide hourly updates to the main plant regarding the level of emission. There is a fourth mobile monitoring station which moves around the surrounding area especially in the wind direction depending on the direction and provides information to the power station regarding the air quality.

- Installation of bores at Ash pond for leachate analysis - Ash ponds are used to store the ash from the plant. At DTPS bottom ash from the furnace is hydraulically transported to ash ponds through pipelines using jet pumps. Fly ash from electrostatic precipitator hoppers is removed by hydro pneumatic system and is mixed with water to form a slurry before transporting it to the ash ponds. There is a high risk of seepage of ash from this ash pond into the nearby creek water. Thus, the ash pond is bounded with suitable retaining wall so as to ensure that no ash slurry is discharged into sea. In order to monitor the seepage of heavy metals from ash in the groundwater and surrounding creek water DTPS has installed bores in areas near to the ash pond to check the water quality. Regular monitoring of water from the bore is done to check the water quality. Provisions has also been made to utilize the ash in manufacturing of cement and in construction of roads.

- Online Ash Analyzers - Online Ash analyzer installed in 2016 which helps in continuous monitoring of the ash content in the coal used by the plant. Online Coal Ash analyzers help the real time measurement of ash in the coal. The system has been installed on the coal conveyor belt which is used in transportation of coal. This has helped the plant authorities to get over the traditional detection methods which is not representative because of their small sample size.

- Installation of Vapor Absorption Machine (VAM) - Vapor absorption machine uses aqueous lithium bromide as absorbent & water as refrigerant. Chilled water is used for Air conditioning system (AC) and for process cooling. By using VAM system for cooling, Ozone depleting gases emission has reduced.

- Use of blended coal - At ADTPS Indian washed coal is blended with imported coal, this result in ash percentage in fired coal to reduce below 30%. By using blended coal generation of fly ash is decreased and particulate matter in flue gas is also much below emission limit.

- Cooling Water System - Since the plat is located on the seashore, once through cooling system using sea water is adopted. The condenser Cooling (Sea Water) effluent water is circulated through a pre-cooling channel, 3.5 km. long and 220 m wide zigzag channel in order to bring down the temperature of cooling water to a value not more than 5oC above inlet water to Condenser, before discharging to the creek. The condenser cooling water is further chlorinated at the condenser outlet to maintain the chlorine level of water.

- Design of the Plant - The plant is predominantly meant for burning of coal. However, provision is being made in the design to burn natural gas as well as oil any of them independently upto 100 percent load capacity in case of gas and 30 percent for oil or in any combination dependent on the availability.

- Coal Handling System - The coal is conveyed to coal bunkers and pulverisers through fully mechanized belt conveyors. From pulverisers to boiler burners the pulverized fuel is fed through pipelines. The wagon tipplers at coal handling system are provided with dust trapping equipment. Adequate water sprinkling arrangements are made at various points like wagon tippling, conveyor transfer points and crushing mills to reduce dust pollution during coal handling. The plant uses Bucket Wheel reclaimers for collecting and conveying the run off coal.

- Prevention and Control of Fire Hazards - The storage and design of fire-fighting system is planned as per fire protection rules. Smog detectors and alarm system with annunciation are installed at critical locations. Portable fire extinguishers are installed at appropriate locations. Hydrants are provided at areas like cold storage, warehouse and boiler house.

Other Environment Friendly Methods Adopted at DTPS

A. Horticulture

Around 300 hectares of area is devoted to the horticulture production. DTPS has shops set up in the colony where it sells this horticulture products. It has different varieties of horticulture crops including Mangoes, Coconut, Chickoo, Apple and all types of vegetables. Around 150 laborers are employed for looking after the horticulture activities of the plant.

B. Sewage Treatment Plant

DTPS has installed a sewage treatment plant where 100% of sewage from building and colonies is conveyed through separate drains to septic tanks. The clean effluent from septic tanks is utilized for horticulture activities and gardening.

C. Use of Waste Plastic in Construction of roads inside the DTPS

Nearly 7 tons of polythene waste has been used to construct roads inside the plant premises. Waste plastic was obtained from Dahanu Municipal Corporation.

D. Green Belt

The open land near the plant has been converted into green belt. DTPS has planted around more than 2 crores of mangroves.

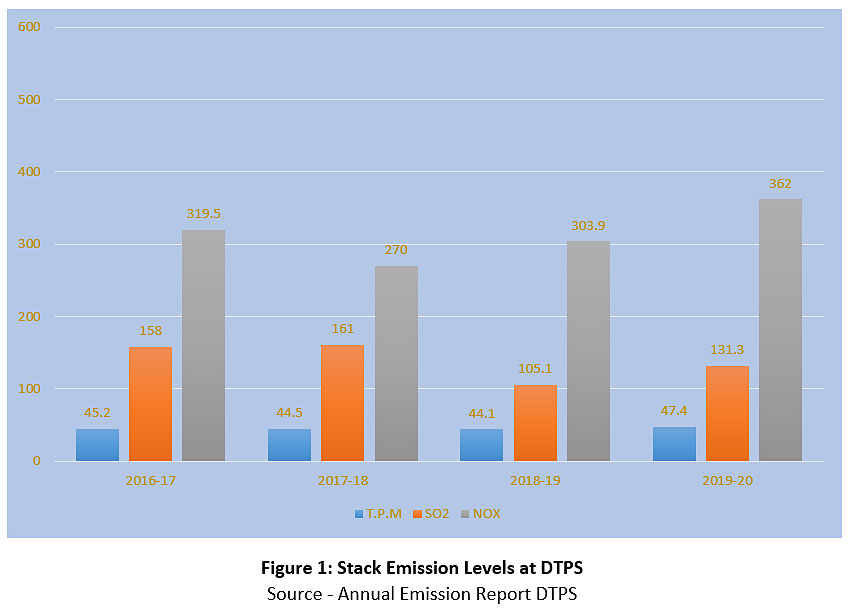

Table 1: Maximum Emission Limit Stipulated by Government of India for Stack Emissions

|

Total Particulate Matter (TPM) at 6% O2 |

100 mg/Nm3 |

|

Sulphur Dioxide (SO2) at 6% O2 |

600 mg/Nm3 |

|

Oxides of Nitrogen (NOX) at 6% O2 |

600 mg/Nm3 |

Source - MoEFCC

|

Figure 1: Stack Emission Levels at DTPS Click here to view Figure |

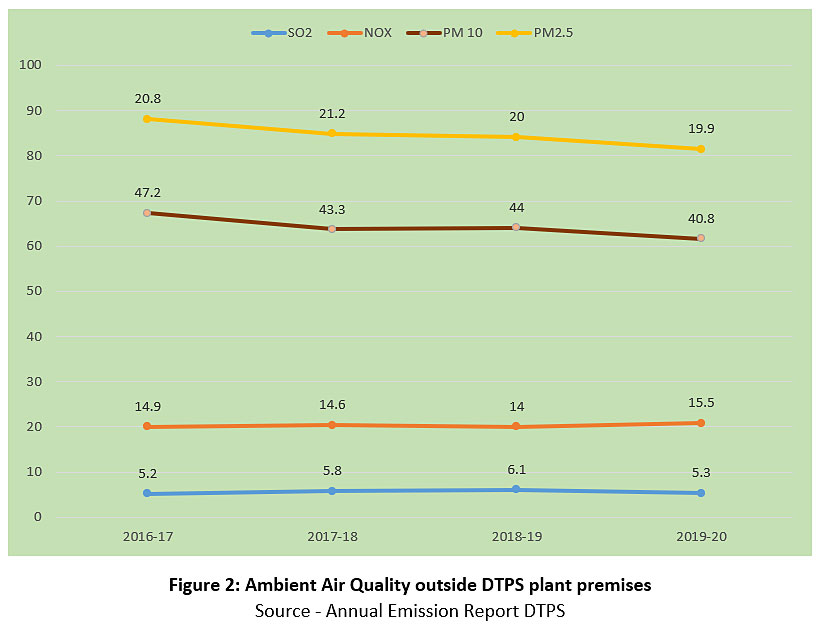

Table 2: Maximum limit stipulated by Government of India for Ambient Air Quality outside Plant Premises

|

Sulphur Dioxide (SO2) |

80 µg/m3 |

|

Oxides of Nitrogen (NOX) |

80 µg/m3 |

|

Particulate Matter (PM) 10 |

100 µg/m3 |

|

Particulate Matter (PM) 2.5 |

60 µg/m3 |

Source - MoEFCC

|

Figure 2: Ambient Air Quality outside DTPS plant premises Click here to view Figure |

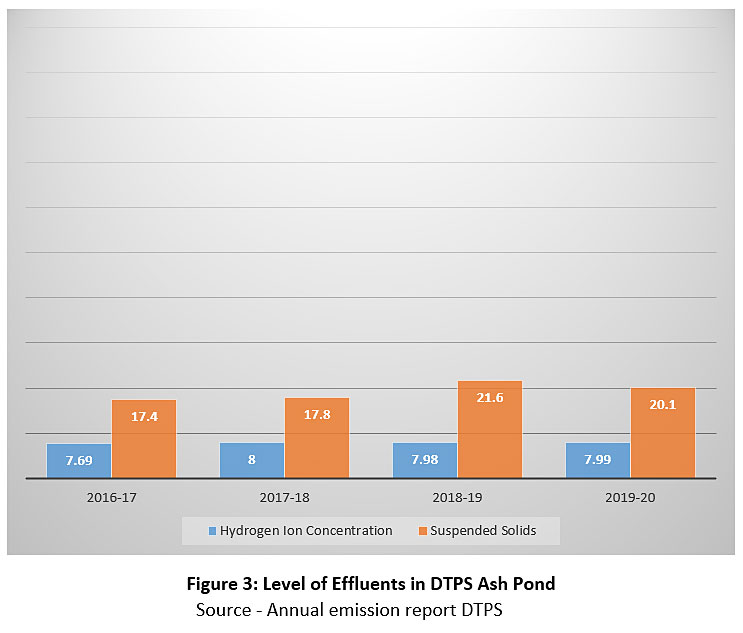

Table 3: Maximum limit stipulated by Government of India for Ash Pond Effluents

|

Hydrogen Ion Concentration |

6.5 - 9.0 pH |

|

Suspended Solids (S.S) |

100 mg/L |

|

Figure 3: Level of Effluents in DTPS Ash Pond |

Results and Discussion

For promoting environmentally and socially sustainable mining it is imperative to conjoin effective implementation institutional and regulatory mechanisms along with technological and process solutions to make this sector more effective. Advanced mine surveying and exploration technologies using 3D seismic surveys can go a long way in mine planning and design stage. Use of surface drilling technologies like hydraulic drills and large excavators for improving loading and haulage will make the mining sector more resource efficient. Governments should give impetus to developing business models and provide small mining enterprises with technical advisory services so that they can undertake sustainable and scientific mining practices.

For effective electricity generation from thermal power plants it is necessary that pollution control technologies be adopted. Sulphur emission can be drastically reduced by installing Flue Gas Desulphurization plant. In order to monitor air quality of nearby areas Thermal Power Plants must install air quality monitoring stations in nearby areas. Electrostatic precipitators play an important role collection of fine ash particles. The efficiency of electrostatic precipitators can be enhanced by use of ammonia dosing system. There is a great possibility of seepage of water from ash ponds in the nearby sources of groundwater. Installation of bore wells near ash ponds will help to monitor the quality of groundwater and help in determining the presence of any heavy metals in water.

Conclusion

Sustainable Mining and Electricity generation is the need of the hour. This can be achieved by retrofitting pollution modern technologies and instruments at mining sites and thermal power stations. The current study undertaken of DTPS has helped to analyze and discuss various methods and techniques which can be used by coal fired thermal power plants to control their emissions. With the rising air pollution levels and its impact on health and environment it is necessary that precautionary measures are adopted by the thermal plants to lower their emissions. Thus environmental management along with electricity generation should be the guiding principle. In order to curb emissions from coal, in addition to the above mentioned technologies, regulatory and enforcement measures must be undertaken by governmental bodies. Electricity Regulatory authorities must see that there is strict abidance of the guidelines provided mining corporates and electricity producers. The government must issue direction for shutting down of the mining and plants sites in case of non-compliance of the emission regulations. It is necessary that a proper plan to shut down old mines and inefficient plants causing more pollution be formulated. It is important that an inter-ministerial steering-cum-monitoring committee comprising representatives from Thermal Corporations, Pollution Control Board, Electricity Commission, Ministry of Power and Ministry of Environment and representatives from private sector be constituted for effective management of mining and power sector of the country.

In 2015, the United Nations General Assembly adopted the 2030 Agenda for Sustainable Development. It formulated Sustainable Development Goals (SDGs), which includes a dedicated and stand-alone goal on energy, SDG 7. SDG 7 calls for an “affordable, reliable, sustainable and modern energy for all”. There is a need for wider interpretation of this goal. Not only the energy needed to be clean and affordable but also the sources of energy should be clean and environment friendly. Energy lies at the heart of both the 2030 Agenda for Sustainable Development and Paris Agreement on Climate Change. Ensuring access to affordable, reliable, sustainable and modern energy for all will open a new world of opportunities for billions of people through new economic opportunities and jobs, empowered women, children and youth, better education and health, more sustainable, equitable and inclusive communities, and greater protections from, and resilience to, climate change.

Acknowledgement

Author expresses special thanks to Mr. Sandip Patil, Manager, (DTPS) for giving approval to survey DTPS. Many thanks to Mrs. Shuchita Sachin, Assistant Manager (DTPS) for her extraordinary support.

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Conflict of Interest

Author(s) declare no conflict of interest.

References

- International Energy Agency. Coal information Report. https://www.iea.org/reports/coal-information-2019. Published June 2019. Accessed May 11, 2020

- Oyuntsetseg, B. Evaluation of the Pollution by toxic elements around the small-scale mining area of Boroo Mongolia. https://www.hindawi.com/journals/isrn/2012/153081/. Hindawi Journal Accessed May 11, 2020.

- Hossain, N. Environmental impacts of coal mine and thermal power plants to the surroundings of Barapukuria, Dinajpur, Bangladesh. Environmental Monitoring and Assessment. https://www.researchgate.net/publication/281762811_Environmental_impacts_of_coal_mine_and_thermal_power_plant_to_the_surroundings_of_Barapukuria_Dinajpur_Bangladesh. Published April 2015. Accessed May 12, 2020.

- Howladar, F. Environmental impacts of subsidence around the Barapukuria coal mining area in Bangladesh. Energy Ecology and Environment, 1, 370-385. https://link.springer.com/article/10.1007/s40974-016-0031x#:~:text=Underground%20coal%20mining%2Dinduced%20land,social%20environment%20and%20so%20on. Published 2016. Accessed May 11, 2020.

- Indian Chamber of Commerce. Sustainable Mining in India, Overview of legal and regulatory framework, technologies and best practices. https://pdfs.semanticscholar.org/f8bd/61cbd7df1df607162dc5524bd2249c2ba2b2.pdf. Published May 2018. Accessed May 12, 2020

- Pachouri R, Saxena A. Emissions control in Thermal Power Stations: Issue, Challenges and Way Forward. The Energy and Research Institute. https://www.teriin.org/sites/default/files/2020-02/emissions-control-thermal-power.pdf. Published January 2020. Accessed May 12, 2020.

- Conservation Action Trust. Coal Kills, Health Impacts of Air Pollution from India’s Coal Power Expansion. http://www.indiaairquality.info/wp-content/uploads/docs/Air%20Pollution%20from%20India%20Coal%20TPPs%20-%20LowRes.pdf. Published January 2014. Accessed May 12, 2020.

- Dandona, L. Impact of air pollution on deaths, disease burden, and life expectancy across the states of India: the Global Burden of Disease Study. The Lancet 2017; 3 (1), E26-39. https://www.thelancet.com/journals/lanplh/article/PIIS2542-5196(18)30261-4/fulltext Published December 2018, Accessed May 12, 2020.

- Impacts of Power Plants. Thermal Watch. https://www.thermalwatch.org.in/environmental-impact-assessment/impacts-power-plants. Published 2014. Accessed May 12, 2020.

- Cropper, M. The Health Effects of Coal Electricity Generation in India. Paper presented at: Agricultural and Applied Economics Association Joint Annual Meeting; August 4, 2013 Washington DC, USA. http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.278.5622&rep=rep1&type=pdf. Accessed May 12, 2020.

- Gunatilake, H. Valuation of Health Impacts of Air Pollution from Power Plants in Asia Research Gate. https://www.researchgate.net/publication/268804937_Valuation_of_Health_Impacts_of_Air_Pollution_from_Power_Plants_in_Asia_A_Practical_Guide. 2013. Accessed May 13, 2020.

- Nkambule, N. Externality costs of the coal-fuel cycle: The case of Kusile Power Station. S Afr J Sci. 113; 1-9. https://pdfs.semanticscholar.org/b873/6dda9cbcca096771ad08710fc4974070e543.pdf?_ga=2. 187908718.776574833.1590430831-698233381.1584039016. Published June 2017. Accessed May 13, 2020.

- Srinivas, S. Methods to control Toxic Air Pollution around Major Cities in India. International Journal of Engineering Research and Technology 6; (2) https://www.ijert.org/research/methods-to-control-toxic-air-pollution-around-major-cities-in-india-IJERTCON051.pdf. Published 2018. Accessed May 13, 2020.

- Health Effects Institute. Health Effects Institute Annual Report. https://www.healtheffects.org/system/files/AnnualReport2018-3_0.pdf. Published 2018. Accessed May 14, 2020.

- Seetharaman, G. Coal here to stay despite India's ambitious goals for renewable energy. The Economic Times. May 11, 2019. https://economictimes.indiatimes.com/industry/energy/power/india-will-not-be-able-to-achieve-its-renewable-energy-targets-anytime-soon/articleshow/69286279.cms?from=mdr. Last Updated 12 May 2019. Accessed May 14, 2020.

- Field Study at DTPS.